Featured Project

Frasehold Farms

Farm History & Evolution

Darryl and Tracy are the 4th generation of family farmers at Frasehold Farms. Darryl’s great-grandfather originally purchased the farm, and his grandparents on his mom’s side bought the farm and raised their 3 kids there while farming for over 60 years.

Growing up, Darryl spent a lot of time at the farm helping his grandparents and realized that’s what he wanted to do. He then purchased the farm from his grandfather in 1997 after renting it from him for several years. Darryl and Tracy moved to the farm in 1998 and raised 3 kids on the farm. Currently, their two daughters work off the farm but help out when they can, and one son is full-time on the farm.

Through the years, the farm has seen several stages of progress. As a child, Darryl fondly recalls his grandfather milking in buckets and cleaning gutters out by hand before adding a pipeline while milking around 20 cows. After they purchased the farm, they put in a stable cleaner and tore out their box stalls to add 2 more rows for milking cows. This allowed them to milk 42 cows and sometimes swing 10 cows in a 45′ x 60′ old bank barn while housing heifers at the neighbour’s farm. After a few years, they purchased the neighbour’s farm as well and continued to house their heifers there. They also rebuilt the floor upstairs in the bank barn so they could drive a tractor on it, upgraded milkers, and performed various small projects along the way.

Transition To Robots & Results

They knew they needed to make a change to move forward, and they began to consider options. They really liked the GEA R9500 milking robot because of the pit that makes it ergonomic and easy to get underneath cows to treat them instead of having to get down on their knees to do it. The all-in-one feature of the GEA R9500 milking robot was also intriguing as it allows for the most consistent milking possible with a robot in terms of cleaning and prepping the teats, milking and applying post dip to the teats, all within the milking unit!

Darryl says that,

“Dairy Lane Systems took the time to stop in and have a conversation with us, answering any questions we had about the GEA R9500 milking robot and then took us to see several barns they had already completed so that we could see it in action and talk with those farmers to learn about their experience. 2.5 weeks into the move, we had no fetch cows; our cows adapted very quickly to the new barn and robot. Now they seem much happier, feed intakes have gone up, and we see cows in heat more naturally, and there is less cramping in cows. The ventilation, along with the fans in the new barn, has taken the stress off the cows due to the heat, and as an added bonus, our workload is more flexible on a daily basis!”

In addition to the GEA R9500 milking robot, the new barn at Frasehold Farms features a 3 row barn deep bedded with recycled cardboard, complete with Jourdain Stabling, GEA Manure Equipment, DLS Fans and Curtains, Maximus Control System, DLS Tip Troughs and Easy Swing Cow Brushes. Heifers and dry cows are all under one roof now as well.

Employee Announcements

There is no new faces to announce at the moment, but check out our open positions at the careers link below to see what's available!

Start A Career at DLS!

We have several great career opportunities. Check them out @ dairylane.ca/careers to see what may suit you!

Employee Spotlight

Josh

Plumber

Joined DLS Biogas April 2022

Josh joined DLS Biogas after gaining experience in a number of different industries and companies. Josh grew up in London and moved to Edmonton, AB, in 2009, where he attended NAIT (Northern Alberta Institute of Technology). There he completed the plumbing apprenticeship program and obtained his Red Seal Journeyman Plumber and Alberta Gas Fitter B certification.

He started his plumbing experience in Fort McMurray, AB; however, when he started his family, he moved back to London, where he worked for Drewlo Holding until moving on to DLS Biogas.

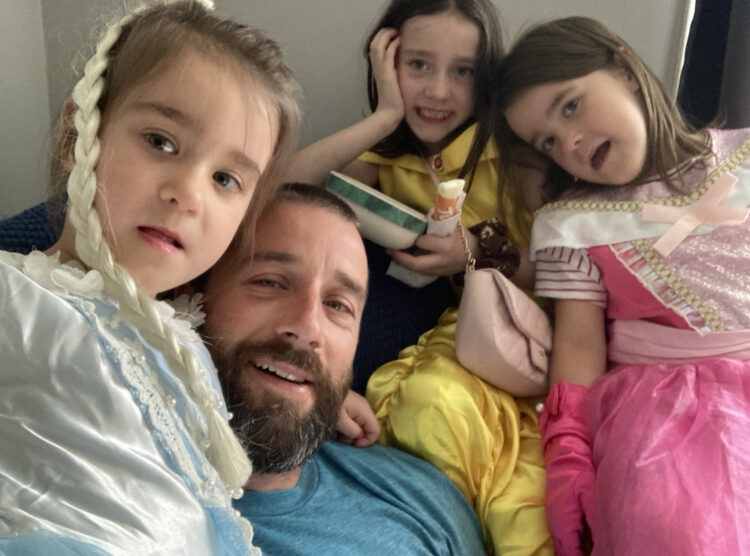

Josh has an active life, he’s the father of 3 girls, and the youngest 2 are twins! He also enjoys a round of golf and getting in the garden when time allows. Josh’s future aspirations are to continue working with the Biogas team building biogas plants!

Product of the Month

VES ECV Fans & ARF Exhaust Fans

Save your cows and your wallet from the negative effects of heat stress with the VES ECV and ARF fans.

The VES ECV fans are push fans designed to provide “Effective Cooling Velocity”, thus the model name ECV! It’s a direct drive fan with adjustable louvers that direct air onto the cows at the high air speeds needed to cool them. The VES EVC features and benefits include:

- Durable, easy-to-clean SMC fiberglass housing with Turbo Cone

- 4 fiber reinforced polypropylene blades on 72″ fan and 3 blades on the 55″ fan

- Minimal-maintenance direct drive with Smart Motor Technology

- Adjustable deflectors to direct airflow to specific areas in the facility

- Scientifically designed to maximize efficiency and airflow volume

See the full VES ECV fan performance specs and features here.

The ARF in the VES AFR fan stands for Air Flow Ratio. This fan model is an exhaust fan perfect for tunnel and cross ventilation setups. It uses a direct drive motor with Smart Motor Technology and is designed to handle extreme weather and harsh environments. The VES ARF features and benefits include:

- Outlet guards come standard

- Durable, easy-to-clean SMC fiberglass housing

- Minimal-maintenance direct drive with Smart Motor Technology

- 4 fiber reinforced polypropylene blades on 72″ fan and 3 blades on the 55″ fan

- Scientifically designed to maximize efficiency and airflow volume

- UL listed & CE certified motors with industry leading 3-year warranty

See the full VES ARF fan performance specs and features here.

JOB PROGRESSION HIGHLIGHTS

Thedford, ON

Stewardson Farms

Another tunnel-ventilated dairy barn started up this year featuring VES fans, DLS curtains, Maximus controller, Jourdain stabling, DLS tip troughs and GEA manure equipment.

Thedford, ON

Gordon Roxburgh Farms

This cross-ventilated facility featuring 7 GEA R9500 Milking Robots just recently started up!

Red Deer, AB

Goselink Holsteins

Here's a video from Goselink Holsteins 40 stall GEA T8900 rotary start up!

Video of the Month

VES Ventilation & Cooling

Creating Animal-Centered Environments with Ventilation & Cooling.