Featured Project

Scott Colony

Scott Colony is a Hutterite colony near Scott, Saskatchewan, that is made up of 20 families totalling around 115 people. Everyone in the colony has a job, from chickens to pigs, beef, dairy, crops, gardening, cooking and much more! The colony began in 1993 with 10 families, and typically when a colony reaches 140 members, they will look for a new place to settle and split the families. In today’s modern world, this is truly a wonder to see and a breath of fresh air to see how they live their lives with such unity.

Farm Evolution

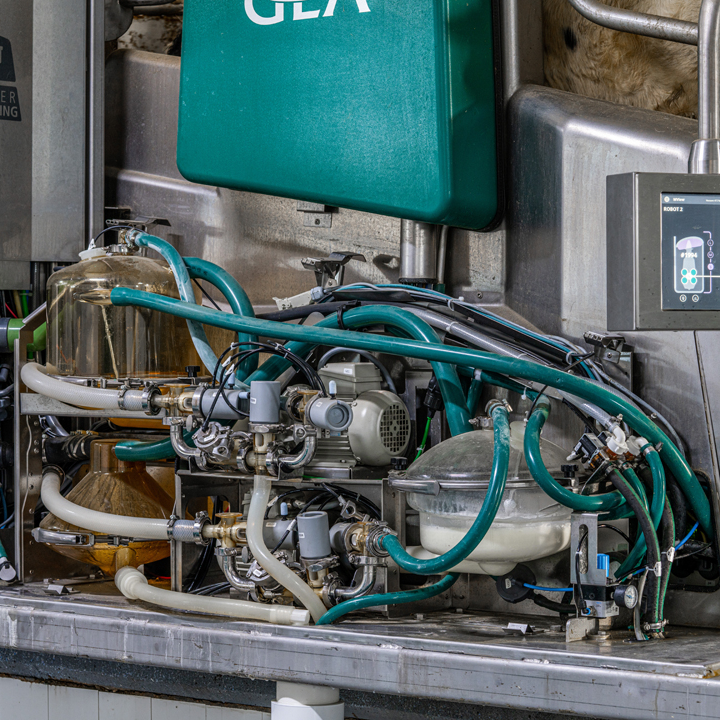

We spoke with George Wurz, who is in charge of the dairy operation and provided insight into how the farm has evolved over the years and how they transitioned from 5 competitor milking robots to 5 GEA R9500 milking robots. In 1993 they started with 75 milking cows in a double 6 herringbone parlour, and after 10 years they outgrew their facility and extended the barn with another 100 cows to 175 as well as the parlour to a double 10. Through the years, they continued to grow, and around 2015 they built a new barn that was capable of housing 350 cows with 5 competitor robots.

A Neccessary Change

They milked for 7 years with the competitor robots, but things were not going as smoothly as they had expected, which led them to look at other options. George said,

“When I saw how the GEA camera system worked, I fell in love, but I also wanted to take time to research and compare the new GEA robot with the other robots and spend time at various robot farms to make the best decision for how we could turn things around.”

George said from within the Hutterite colonies, he heard good feedback about the GEA R9500 robot, but he wanted to see and hear it from an “outsider.” He spent time on two separate occasions with Tim Hofstra at Detimdale Holsteins (see their project here!). He went there towards the beginning when their cows were still transitioning from their previous tie stall setup, and he kept in contact with Tim and saw his production increase in two months from 20 litres to 36 litres. He was amazed at the improvement and the attachment speeds.

Everyone George talked to spoke positively about DLS and their service. George said,

“They will show up when you need them to. During the installation, they had 4 guys here, and they all communicated well together. They are a great group of people!”

The installation went smoothly. It took 1 month from start to finish. Their cows stayed in the same barn, and we replaced one milking robot at a time so that there was no downtime in milking.

Results

The results are going well with the new robots! The cows are milking 38KG (up from 35KG) with a bacteria count between 6-7 (down from 25-30) and a SSC at 120,000-130,000 (down from 200,000 -300,000). Butter fat is at 4.2%.

George said,

“This robot is more cow friendly. It’s wide open rather than being boxed in, and you can see when the cow comes in, she is more relaxed. It’s a way different system! Attachment times are smooth and fast, and I like that it is capable of draining individual quarters with any cow with high SSC. It does a great job prepping and cleaning the teat, as well as the coverage on the post dip. I also like that as soon as the exit gate opens, it closes the feed manger and out goes the cow without her waiting around eating feed. It’s an AMAZING machine. Everyone in the colony is happy. Anyone is welcome to come and visit!”

Employee Announcements

There is no new faces to announce at the moment, but check out our open positions at the careers link below to see what's available!

Start A Career at DLS!

We have several great career opportunities. Check them out @ dairylane.ca/careers to see what may suit you!

Employee Spotlight

Cory

Welder/Fabricator

Joined DLS May 2018

Cory joined DLS after gaining a lot of experience in the Canadian west! Cory was born in Chatham, and after graduating high school in Tilbury, he then headed west and welded tanks for the oil field and I-beam for powerline supports.

He moved around and worked in the Grand Prairie area for about 6 years. From there, he achieved his red seal in welding at NAIT (Northern Alberta Institute of Technology) in Edmonton and SAIT (Southern Alberta Institute of Technology) in Calgary. He worked a few more years there before deciding it was time to head back home to Ontario.

Currently, Cory spends most of his days in the fab shop mentoring our newer welders and pushing out some high-quality work! Occasionally he works on-site, assisting the install and service teams with their welding needs.

When he’s not working, Cory enjoys spending time with his family, fishing, and playing and watching hockey – that sounds like a true Canadian boy 😊!!

Cory is the father to his 4-year-old son Quinn and 15 -year-old stepdaughter Kaydence. Cory and his fiancé Cassaundra plan to get married in the near future and celebrate by taking the family on a cruise in the sunny south!

Product of the Month

GEA R9500 Milking Robot (ALI) Products

Over the last several years, GEA has continued to make great strides in establishing and building upon their GEA R9500 milking robot to have a strong competitive advantage and perform at a high level for today’s milking herds. Here are some key features of the GEA R9500 robot and why going GREEN is trending!

In Liner Technology

GEA is the only milking robot on the market that performs everything in the liner. What this means is after the milking unit is attached to the cow, the cow receives teat stimulation, teat cleaning, forestripping, milking and post dipping, all within the liner of the milking unit! This helps to harvest the best quality milk possible and provides the most accurate post dipping coverage compared to spraying.

Learn more about In Liner Technology here.

G5 Time-of-Flight (TOF) Camera

The G5 Time-of-Flight (TOF) Camera comes with the best technology that provides precise teat detection for fast milking attachments. Fast attachment times are critical to making the robot herd as efficient as possible.

Manual Attach

The GEA R9500 milking robot allows the farmer to switch to manual mode and manually attach a cow. Why would this be important in a robot barn? Many dairy producers with the R9500 robot have found this to be an excellent feature when training fresh heifers on the robot for the first time. After manually attaching for a few milkings, fresh heifers are usually trained and will now walk into the robot and be attached on their own. This can also be beneficial for startups for training cows that have odd udders/teats. The more they are milked, the more the robot will learn how to attach the cows with odd udders/teats.

GEA DairyMilk M6850 Somatic Cell Count Sensor

This optional feature monitors each udder quarter individually throughout the entire milking process. This will detect any negative signs early on, which will reduce treatment time and help provide the necessary data to maintain the overall herd health.

Learn more about the GEA DairyMilk M6850 Somatic Cell Count Sensor here.

Learn more about the GEA R9500 milking robot here.

JOB PROGRESSION HIGHLIGHTS

Red Deer, AB

Goselink Holsteins

This 40 stall GEA T8900 rotary project is shaping up well!

Diamond City, AB

Leeuwenburgh Dairy

An upcoming GEA R9500 milking robot barn (4 robots) complete with Jourdain stabling, DLS ventilation, Daritech manure pumps and the Maximus controller.

Olds, AB

Bertens Holsteins

Construction is in progress for this upcoming DLS turnkey operation including a 80 stall GEA rotary project, stabling, ventilation and manure equipment.

Video of the Month

Detimdale Holsteins GEA R9500 Robot Facility

Watch Tim Hofstra of Detimdale Holsteins talk about their decisions for going with the GEA R9500 milking robot for their new 6 row perimeter feed 2 robot barn, and check out some of the unique features the GEA R9500 milking robot has to offer!