Featured Project

Windulan Holsteins

Mike and Theresa Portena both immigrated with their respective families to Canada from the Netherlands in 1988. After getting married, they farmed together with Mike’s parents and his brother Rick Portena. In 1997, Mike and Rick each started on their own farms, both located outside of Monkton, Ontario. Since 1997, Windulan Holsteins has undergone various levels of growth and transitions. What began as a double six parallel parlour is now a 50 stall external GEA rotary. Today, alongside Mike and Theresa, the next generation is heavily involved in the farm’s day-to-day operations.

Mike and Theresa have four children, Joanne, Gina, Ryan and Marco. Joanne works off the farm as an Immigration Consultant, which helps with her on-farm responsibilities that include hiring foreign workers, bookkeeping and payroll. Gina performs barn work including milking, breeding and animal health. Ryan handles the three “F’s” – fieldwork, feeding and fixing. The youngest, Marco is currently in agricultural school at Lakeland College in Alberta.

The Timeline

1997

Double 6

Parallel Parlour

1999

Double 9

Parallel Parlour

2002

Double 12

Parallel Parlour

2016

Internal

40 Stall Rotary

2021

External

50 Stall Rotary

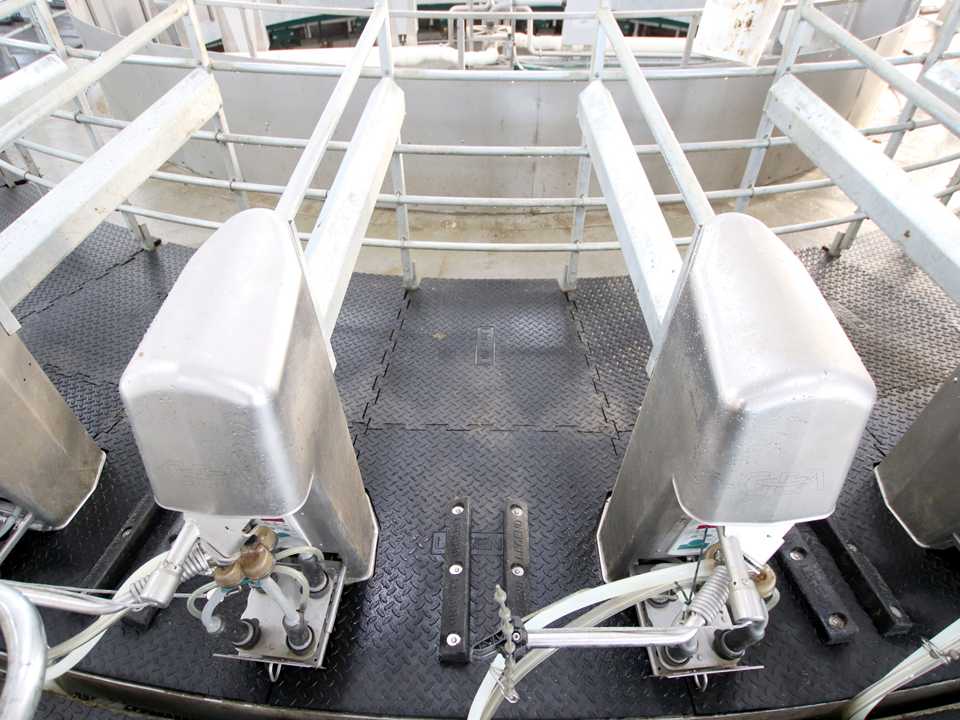

Rotary Features

The 50 stall rotary is a GEA DairyRotor T8000 Series rotary that features GEA milking equipment, including GEA IQ milking units and DemaTron 70 controls. This rotary is using the PosiBall Universal Hose Support, which is designed to hang the milking unit straight leading to a more complete and even milk-out. A Legend rubber cow deck ensures the cows have a comfortable experience on the rotary. Legend rubber leg separators allow the cows to stand better on the deck, making attaching the milking units easier.

Along with the new GEA rotary, Windulan Holsteins transitioned to the GEA Cow Scout ID System with neckbands. In the return lane of the rotary is a stainless steel DLS Sort Gate to sort the cows with the new system. Gina Portena says,

“The new ID system has rumination time statistics which I have found to be a big help in identifying sick cows and treating them sooner. This is especially important to us as we make great efforts to catch sick cows early. We bring them out of the free stalls into a pack area and milk them separately in a small single 6 hospital parlour.”

Milking Improvements

Some key positive results since transitioning to the new rotary include a more efficient cow flow traffic system that has been much easier to bring the cows in and out. A foamer at the pre and post-dip stations has allowed for optimal teat coverage, leading to less mastitis. SCC has also decreased. The cows are milking out quickly and efficiently, and with milking 550 cows, they have cut the milking time down to about 2 hours 30 minutes. Previously they were running at a little over 3 hour milk time. On the exit side, 5 cows can comfortably exit the rotary at a time, allowing for minimal stopping time.

Gina Portena says,

“Cow comfort has increased tremendously! The cows enjoy coming up to the rotary, and they stand extremely still on the platform. A combination of cow comfort, better cow flow and better milk flow has contributed to successfully decreasing the overall milking time and decreasing SCC. We also really like how user friendly the GEA rotary system is for training new employees.”

Employee Announcements

DLS is pleased to welcome the following people to the Dairy Lane team:

Start A Career at DLS!

We have several great career opportunities. Check them out @ dairylane.ca/careers to see what may suit you!

Employee Spotlight

Anthony Helder

Logistics Coordinator

Joined DLS March 2011

In March this year, Anthony hit the 10-year mark with DLS!! He started as a full-time employee working in the parts department and also did some delivery work. From there, Anthony moved into the Stabling Inventory Coordinator position, where he spent several years as the key contact at DLS to orchestrate Jourdain stabling deliveries to local DLS job sites and dealers across Canada. Anthony also performed inside sales work but has since moved into his current role as the Logistics Coordinator.

Before his time at DLS, Anthony worked at a greenhouse part-time throughout high school. After high school, he worked in his family’s business (Helder Auto Body) for about 6 months before coming to DLS and here he is 10 years later!!

When he’s not working at DLS, Anthony enjoys playing hockey – he plays goal twice a week and, despite the ongoing heartbreak, remains a die-hard Leaf fan! Anthony has an interest in cars and enjoys working on and driving his 1981 Camaro Z28.

Anthony plans to remain with DLS, continuing to learn and grow with the company.

Product of the Month

GEA DairyRotor T8000 Series

The GEA DairyRotor T8000 Series rotary is designed for optimal cow comfort and fast, efficient cow loading and exiting.

Overall this rotary is a well-built robust system that was built to last! Farmers have the flexibility to customize the rotary to their cow’s size and needs. The rotary features a low-profile rotary stall engineered for fast, smooth cow flow on and off the platform. Smooth, rounded stall corners on the cabinets promote cow comfort and safety. Nylon wheels are utilized to keep the rotary spinning; these have proved to be very durable and require little maintenance. The undercarriage components are very quiet during the milking, making for a more enjoyable milking experience.

In terms of service, the GEA DairyRotor T8000 Series was designed for serviceability with the ability to maintain it while running. One key service feature is the in-line design of the detacher cylinder housing, which makes for less frequent maintenance and is more service-friendly.

With GEA’s proven technology and a great deal of DLS experience in rotary milking facility design, we can custom design and layout your milking facility to maximize your milk production and ROI while providing great cow comfort and an enjoyable environment for the milkers.

JOB PROGRESSION HIGHLIGHTS

New Liskeard, ON

Flinkert Farms

A retrofit DLS individual indexing double 10 parlour installation installed by Centre Laitier!

Monkton, ON

New Morning Holsteins

This GEA 60 stall rotary is taking shape! The rotary is being connected to the tunnel ventilated DLS Structure we built in 2014.

Conn, ON

Henria Holsteins

The cows recently moved into this new dairy barn featuring Jourdain stabling with twin rail mounted US stall loops!

Windulan Holsteins 50 Stall Rotary

See Windulan Holstein’s milking in action and listen to Gina Portena talk about their new 50 stall GEA rotary!