Featured Project

Walker Farms

Walker Farms is a leader in the Ontario dairy industry with over 60 years of actively growing their dairy farms and operating Walker Sales. This year, Walker Farms has introduced a new phase in their growth and evolution with an on-farm milk processing plant featuring A2 Protein Milk.

“We believe in the dairy industry and the great nutritional benefits of dairy products for the consumers. In recent years we have seen a downward spiral of consumer interest in dairy. We saw a need for change in the market, and with this need came an opportunity to play a positive role to promote the dairy industry as a whole and directly connect the farmer and the consumer” (The Walker Family).

Preparation

Around 2012, the Walker family began to consider the idea of on-farm milk processing, and their interest deepened about 6 years ago. They began to invest a considerable amount of time researching and planning how this could look for their farm by travelling and visiting other plants in North America and Holland. Their goal was to build an on-farm processing plant that would meet the size of their dairy operation, and they worked very closely with one of the DLS owners, Mike van Logtenstein, on the plant drawings and the planning process. John Walker said,

“We went through many revisions from the beginning to where we ended up, as we visited different plants and determined what systems made the most sense for our farm. We appreciate all the work and energy Mike put into this project, and we value the great relationship we have had with DLS and the van Logtenstein family for over 30 years”.

Once they were committed to building the plant, they decided to go a step further and began planning to produce pure A2 Protein Milk products. In preparation for producing their A2 Protein Milk, Walker Farms tested their cows using a hair sample to determine which cows produced A2 Protein Milk. Most Holstein herds are naturally 30-40% A2, and after adopting an A2 identification and breeding program they had more than enough A2 cows to meet the production demand they initially planned to produce and sell. The milk processing plant started up in June 2021 and is currently processing 50% of their daily A2 Protein Milk production. Today their breeding program exclusively uses A2 genetics. Regarding barn logistics at milking time, their A2 cows are separated into groups, and they are milked separately from the A1 and A1/A2 cows to ensure their A2 Protein Milk remains purely A2.

A2 Protein Milk

A2 Protein Milk is considered “the original cow’s milk”, and it shares the same A2 proteins as buffalo, goat and human breast milk – making it easier on digestion for some people. The A2 genes originally dominated, but a natural mutation occurred thousands of years ago and introduced a new A1 dominant gene to dairy cows. Today, many Holstein cows carry this A1 gene, which leads to conventional milk often having a blend of A1 and A2 proteins. In the 1990s, researchers in New Zealand discovered the A1/A2 gene difference and found key benefits with A2 milk in relation to bloating and dairy indigestion.

The genetic differences between the cows results in slightly different amino acid sequences for A1 and A2, which causes them to become different proteins. As different proteins, they have different paths of digestion. Due to their difference in digestion, the A1 proteins in milk can potentially cause bloating and gas that mirrors the symptoms of lactose intolerance. While many people experience dairy intolerance, most assume that they are lactose intolerant (without being tested) when they may just be sensitive to the A1 proteins in conventional milk.

“We have already heard many stories of people who experienced these symptoms or had young children who experienced these symptoms of indigestion with dairy, and after trying our A2 Protein Milk, they were pleasantly surprised to feel satisfied and normal instead” (John Walker).

For those diagnosed with lactose intolerance, it is important to note that A2 Protein Milk does contain lactose unless it is listed as lactose-free A2 milk. Learn more about A2 Protein Milk and A2 FAQs on their website @ Walker Farms A2 Protein Milk.

Carbon Footprint

In addition to the digestive benefits of A2 Protein Milk, the Walker family has also seen positive progress from their on-farm processing as they work to reduce their carbon footprint; they are shortening the supply chain and supporting a more localized food system. Operating everything from their family farm in Aylmer, Ontario, they truly control their milk production from farm to table and continuously look for ways to elevate their sustainability practices on-farm. The Walkers grow their cow’s feed in their own fields (alfalfa/corn/wheat), they house and milk the cows on-site, and their milk is produced, processed and sent out for delivery in less than 150 meters. They sell local, fresh milk to their surrounding communities, and their customers love to know exactly where it came from!

Community Roots

Walker Farms has a deep history in the Aylmer and surrounding area. The local community has always been important to them. Reminiscing about the old Aylmer ice cream shop that was once on Talbot St., they saw a natural way to contribute and invest back into their local community through their new venture by opening a dairy bar. John Walker said,

“We saw a need for a local old fashion dairy bar in our community, and the success and positive feedback we have received pays tribute to how much the community loves it. It has become a great place to not only showcase our milk products but also to support other members and local businesses within the surrounding community”.

The Dairy Bar is located on Highway 3 just east of Aylmer at 560 Talbot St. East, and in addition to their milk, offers products from local partners such as Shaw’s Ice Cream, Grandma’s Oven, Spicer’s Bakery, Mr. Amish and Las Chicas. If you’re in the area, be sure to stop by, check them out, and don’t leave without trying out their milkshakes!

A Growing Family

John Walker said that,

“Another key factor that drove us to pursue milk processing was our desire to keep growing and diversifying the farm for a growing family.”

Currently, parents Jon and Linda and children John, Scott, Dayna and Clint are all actively involved in the day-to-day farm operations. The youngest child, Jane, is currently in University but works on the farm throughout the summer. You can learn more about the history of the Walker family and Walker Farms at Walker Farms History Time Line.

Products & Locations

Their main products include a 1% and 2% partly skimmed A2 Protein Milk, 3.25% homogenized A2 Protein Milk, and a 2% partly skimmed chocolate A2 Protein Milk. An interesting fact about their chocolate milk is that they were able to create a rich cocoa taste with about half of the sugar that would typically be seen in chocolate milk. Soon, they will be adding cream into their product mix!

We encourage you to visit Walker Farms website, Walker Farms, to view their A2 Protein Milk products and be sure to check out the Store Locator to see where you can get ahold of their milk!

Employee Announcements

DLS is pleased to welcome the following people to the Dairy Lane team:

Start A Career at DLS!

We have several great career opportunities. Check them out @ dairylane.ca/careers to see what may suit you!

Employee Spotlight

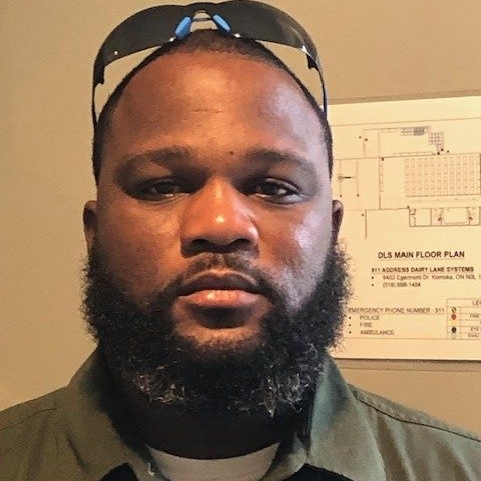

Jeremy Tripp

Warehouse/Yard Attendant

Joined DLS December 2013

Jeremy has been with DLS for almost 8 years! He started out as a full-time employee with split duties. 50% of his time was spent on the Warehouse/Yard team and the other 50% delivering equipment to farms. As time moved on, Jeremy transitioned full-time into the delivery position for a few years before making a move to rejoin the Warehouse/Yard team full time with a focus on the stabling equipment.

At the age of 14, Jeremy started working part-time at Cuddy Farms. He remained there for 20 years, progressing into new opportunities becoming a lead hand and an assistant manager. Then, along came DLS and the rest is history!

He’s an outdoors guy who enjoys fishing, hiking in new areas and camping. He also likes racing and often attends local races at the Delaware Speedway or the Grand Bend Motorplex.

His dream is to one day become self-employed and live on a small hobby farm with his wife, sons Owen and Benjamin and his eight-month old baby girl Andrea.

Product of the Month

Mueller Milk Cooling

The Paul Mueller Company is recognized globally for their milk tanks and milk cooling equipment. Mueller sets a high bar for quality with everything they produce, and in fact, they believe that:

“The only quality that matters is quality that works for life.”

The Mueller product line includes milk cooling bulk tanks that are available in 13 sizes ranging from 2,271 L to 30,283 L, control panels that provide farmers with full control over the essential blending, cooling and cleaning functions of the cooler to ensure the milk quality stays pure. The most common control panel we use is the HiPerForm III. Heat exchangers that allow farmers to use a pre-cooling system to pre-cool the milk before the milk enters the milk cooler, saving both energy and money while improving milk quality. Heat recovery units that recover wasted heat from the milk coolers condensing unit and use it to heat water for other purposes.

See Mueller’s history timeline and learn more about their extensive product line at The Paul Mueller Company.

JOB PROGRESSION HIGHLIGHTS

Ormstown, QC

Homestead Lodge Holsteins

We were very excited to perform our first DLS curtain install in Quebec! We previously worked with them with Jourdain stabling in their dairy barn, and they also have Jourdain stabling and DLS panel fans in this barn renovation.

Monkton, ON

New Morning Holsteins

The underground work and concrete has been in progress for an upcoming 60 stall GEA rotary that will be positioned next to the tunnel ventilated DLS Structure we built in 2014.

Sarnia, ON

Forbesvue Farms

An upcoming Double 16 Vertical Lift Parlour with Individual Indexing. This unique build will incorporate a tunnel under the cow cross-over and equipment subways under the cow decks.

Walker Farms Milk Bottling Process

A quick video showing how the empty bottle is labelled, filled, and packaged up – ready for the consumer’s hands!