Featured Project

Ijsseldijk Dairy

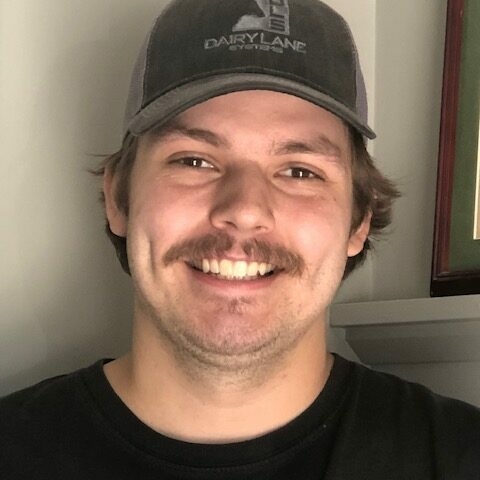

Tino and Paul Ijsseldijk are two brothers who sold their family farm in Holland to move to Canada to operate a 120-cow dairy farm in Springfield, Ontario. In the past 22+ years, numerous modifications and renovations have been made to improve the health and comfort of the overall herd, from calves to milking cows. There have been several expansions and renovations to the main dairy barn, they built new heifer and calf barns, and the most recent expansion was the 50 stall GEA rotary parlour built with more cow housing, which connects to the main dairy barn. Currently, the Ijsseldijk’s are milking 900+ dairy cows. In the picture above, from left to right are Kathy (Herd Manager), Tino (Owner), Paul (Owner) and Porter (Paul’s son).

2018 Transition to Rotary

The rotary start-up was in February 2018, and the initial transition took three days for the cows to get used to walking onto a moving rotary. Paul said,

“We had a lot of assistance at the beginning provided by Dairy Lane Systems employees to help achieve a smooth and successful transition. After we were up and running with a smooth flow of cows from the pens to the parlour, we calculated our savings on labour costs and milking times to be 1.5 hours minimum per milking compared to the previous double 24 parallel parlour. A very fast, smooth and effective flow of cow traffic is the main area we see improvement in our transition to the rotary parlour.”

2022 Rotary Bail Retrofit Project

In 2020, GEA released the new T8900 series of rotary parlours with their new AR24/7 Stainless steel rotary bails.

- The new bails are made from hydroformed stainless steel, eliminating any sharp edges that could injure cows and making clean up easier.

- The new bails are also substantially lower allowing cows to enter and exit the rotary platform more easily.

- The new bails can be angled forward or reverse 15 degrees to meet the farm’s preferences and requirements

- The new bails can be configured with PosiGuide arms (milking units stay above the deck) or with PosiForm Arms (milking units drop below the deck)

Paul and Tino immediately saw the benefits this new bail offered and began to investigate how it could be retrofitted on their existing parlour. Together with the staff at DLS a method was developed to replace these bails during the short window of time between milkings using custom fabricated adapter plates.

Paul and Tino decided to angle the bails 15 degrees – Reverse. This allows the PosiGuide Arms (milking units stay above the deck) and milking units to stay on the leading bail, eliminating extra steps during the attachment process.

Another unique change was lifting the milk hose nipple 6″ off the rotary deck. This allowed for a shorter milk hose to be used (26”) and has eliminated any cows stepping on hoses.

Project Results

Since the renovation, the Ijsseldijk’s have found the rotary cow flow to be exceptional. The cows find the new AR24/7 bail to be extremely comfortable. The cows walk on and off the deck confidently knowing that there are no sharp edges or pinch points.

With the modified milk hose inlets and short milk hoses they have achieved a practical, effective, and simple milking procedure. Even employees with little experience have an easy time attaching the milkers as hoses and units are more out of the way. They also really like that when the milking unit detaches, it does not hit or affect the cows in any way to ensure their comfort level is not negatively impacted.

Milking time has been cut nearly in half even with milking more cows! Previously it took 5 hours per shift to milk 700 cows in their double 24 parallel parlour, now post-renovation, they are milking 900 cows in 3.25 hours or less per shift. Cow comfort is the best they have seen, and mastitis and udder rot have nearly been eliminated from their herd.

There is one other key feature that was originally installed on the rotary, although not part of the recent renovation, that is worth mentioning here as it has played a key role in cow udder health. A backflush system cleans each milk unit between each cow milking. This prevents an infection between cows, and has aided in achieving an almost mastitis free herd.

Paul says that

“Dairy Lane Systems did a fabulous job in helping us achieve our goals, and they made the setup flawless for us to operate. The crowd gate has an operation unit at the front and the back of the holding area, making it easier for those moving the cows into the holding area and the milkers to work together. Sensors are located at the entry in case a cow isn’t on the deck fully to ensure their safety if someone doesn’t catch it immediately. The cow flow in the barn was well planned for efficient shifts and the successful health of the herd. It has proved to be a stress-free working environment for employees and owners. Also, the rotary, with its stainless steel material, is easy to clean and maintain.

We are always continuing to do research to ensure that we are providing the best comfort and health for the cattle and our employees.”

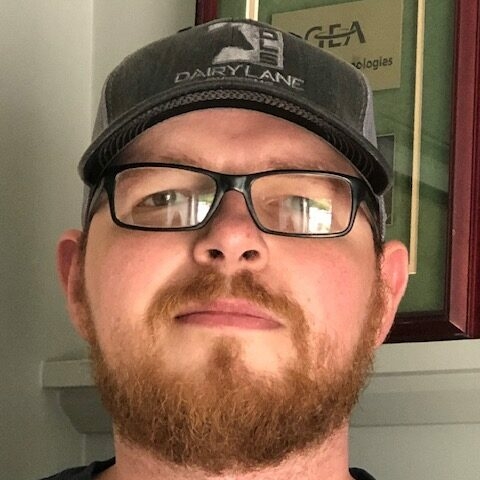

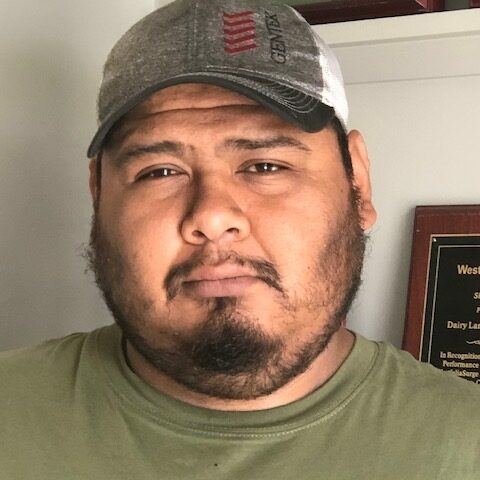

Employee Announcements

DLS is pleased to welcome the following people to the Dairy Lane team:

Start A Career at DLS!

We have several great career opportunities. Check them out @ dairylane.ca/careers to see what may suit you!

Employee Spotlight

Enid Bull

SK Administration/Parts Coordinator

Joined DLS April 2021

Enid was born and raised in Regina, Saskatchewan. She began her working career as a Librarian and worked in the newsroom for the Regina Leader Post Newspaper, where she met her husband Vaugh. At the time, Vaugh had just taken over the family dairy farm as the 3rd generation farmer. In 1991 with the birth of their 4th daughter, Enid and Vaugh decided to save the expense of daycare and a hired hand by bringing Enid home to work full time on the farm and watch the children. Enid recalls this time as an excellent opportunity to be a stay-at-home mom and teach their girls what they call today a great work ethic.

They had a 50 cow Surge tie stall barn with a registered, closed herd that they were very proud of, as well as a small grain operation that they were working on expanding. In 2007 they decided it was either time to upgrade the dairy or sell the cows and quota, and with none of their girls interested, they decided to sell.

On January 1, 2009, the cows were gone, and Dairyland Agro approached Enid to fill in for the Office Manager while the Office Manager went on maternity leave. After the maternity leave Enid continued to work with the Office Manager in a job share role for one year before they decided to stay home permanently. Enid worked there until DLS bought the dairy division of Dairyland Agri in 2021. Enid has been enjoying the challenges of working for a new company and interacting with all her new co-workers. In reflection on the transition and her time with DLS for almost a year and a half now, Enid told us that:

“The Saskatchewan dairy industry was ready for a change, and I believe that DLS and General Manager Herman Guenter was exactly what was needed to revitalize things and bring in fresh ideas.”

Enid’s time away from the office is spent with her kids, grandkids (5 grandsons & 1 grandaughter), and cheering for the Riders – mind you, she says that has been tough this year!

Product of the Month

GEA DairyRotor T8900 Rotary Parlour

GEA has designed the T8900 external rotary milking parlour for efficient milking and cow flow processes and top performance. It is available for mid-sized to larger herds with options ranging from 32-120 milking stalls. This rotary is as robust as they come giving farmers a strong sense of operational reliability.

Cadillac Like Comfort

The T8900 external rotary is the Cadillac of rotaries when it comes to comfort for both cows and milking operators. The bails have a low profile with smooth surfaces and rounded corners that allow the cows to smoothly enter and exit the rotary, and the positioning of the milking units is very user-friendly with a well-designed positioning arm.

Control System

The GEA DairyMilk M6330A rotary control system accompanies the rotary and is a high-speed network that allows you to visualize and control the milking processes in real time. All the details milking operators need to see are available on screen: milking stall occupancy, animal data and current milking results. ID systems are also in place to recognize when the cow enters the rotary and what stall she is being milked in.

Hygiene & Cleanliness In Mind

The T8900 rotary deck has a slight slope for water and other liquids to flow away from the cow and milker into a groove in the middle of the rotary. There are also splash shields in place to protect the electronic milking equipment.

Customizable To Your Herd

The T8900 rotary has several options to allow you to make the ideal setup for your herd. For example, you may choose a 75° or 90° milking stall position and a V-shaped or parallel-shaped entry style.

Reliable Drives & Rollers

According to GEA, this is the most powerful rotary parlour in their DairyRotor product line. It has reduced friction, less running resistance and the lowest wear and tear utilizing a unique quad roller drive and heavy-duty nylon rollers.

Learn and see more about the GEA T8900 rotary parlour here.

JOB PROGRESSION HIGHLIGHTS

Picture Butte, AB

Leeuwenburgh Dairy

Barn construction is in progress for this upcoming 4 GEA R9500 milking robot barn with Mueller cooling equipment, Jourdain stabling, DLS ventilation, and GEA manure equipment!

Centralia, ON

Hoonaard Farms Inc.

Congrats to the Hoonard family on their recent move in with this turnkey DLS free stall and parlour operation!

Zehner, SK

Darian Farms

We recently installed 2 DLS sort gates in their existing milking facility, and we will be working on several renovation projects including installing a parlour ID upgrade, Jourdain stabling, converting the barn to tunnel ventilation, and a sand lane to convert the barn to sand bedding.

Video of the Month

Brennan Bros. Farms Project

Watch this turnkey DLS operation at Brennan Bros. Farms featuring a D-8 DLS/GEA parallel parlour with a 4 row center feed alley sand dairy barn.