Featured Project

Dairy Lane Systems

As our loyal readers know, we enjoy sharing a Featured Project each month to highlight one of our customer’s stories and their project. We’re changing it up for this month to fill you in on some things we’ve been working on behind the scenes. The first change we’ll note, as it is pretty apparent, is our E-Newsletter is now in a new format within our brand new website! This new format is more user-friendly with no need to download a PDF, and it is responsive for all the mobile readers out there. After you’re done with the E-Newsletter, take a tour around the new site, we’d love to hear your feedback at marketing@dairylane.ca. Now let’s get to it!

If you haven’t been to our shop in the past year, the first thing you’ll notice as you pull into DLS is a new building with DLS logos across from the main office! This building is our new dedicated fabrication facility. For many years the former fab facility was a small area within our main L-shaped facility. Space was a challenge when it came to fabricating large items such as parlours and crowd gates. Mike and John van Logtenstein said,

“We invested in new equipment with more advanced technology that would allow us to produce more parts in-house. Ultimately our goal was to produce higher quality products for our customers at a competitive price.”

Some of the equipment that we invested in includes a robotic welder, laser cutter, a high accuracy 6 axis press brake and a CNC triple stack rotary draw bender. Numerous half-ton cranes are situated throughout the fabrication facility, and we have one large crane rated at 5 tons. Now our employees can move heavy or awkward shaped equipment with ease, and in a safe manner.

Within the fabrication facility, we currently fabricate the following items on an ongoing basis:

- Complete parlour systems (stainless steel cabinets, hot-dip galvanized parlour stalls and parlour frames)

- Hot-dip galvanized crowd gates

- Stainless steel sort gates

- DLS stainless steel tip troughs

- Numerous types of hot-dip galvanized DLS specialty gates for stabling

- Numerous smaller scale items such as grates, galvanized stands, various hardware and mounts, manure drop doors and much more!

In addition to this, to best suit the needs of our customers, we always seem to have an assortment of custom projects on the go too!

With the expansion of the fabrication facility and the increase in our production levels, especially as it relates to the milking parlours, we decided to restructure and reorganize that division of the company to a new company, DLS Manufacturing Inc.

Another big piece of news for DLS took place earlier this year. We are excited to publicly announce that we entered into a distribution agreement with GEA to sell our parlour stalls exclusively through the GEA dealer network! As a long-time GEA dealer, we have always had a great working relationship with GEA, and we are looking forward to growing together in the parlour department. For our local customers, we maintain the direct sale of our parlour stalls within our primary milking territories.

While all of these changes were occurring behind the scenes, we have also been busy working on our customer projects. We would like to express our appreciation to YOU, for putting your confidence in us and for allowing us to have the opportunity to play a part in improving cow comfort and providing excellent quality dairy products to today’s consumers.

If you would like to learn more about how DLS has evolved over previous years, we invite you to see our history milestones.

Employee Announcements

DLS is pleased to welcome the following people to the Dairy Lane team:

Start A Career at DLS!

We have several great career opportunities. Check them out @ dairylane.ca/careers to see what may suit you!

Employee Spotlight

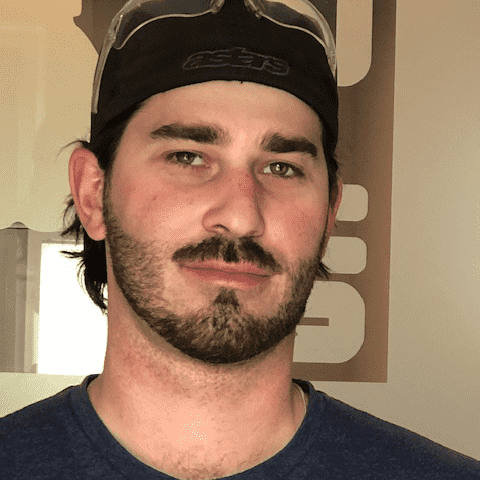

Steve Gare

Dairy Equipment Installation Technician

Joined DLS December 1990

Steve is our most tenured employee with 30 years and counting at DLS! He started working with dairy equipment in 1988 with the previous Surge and Mueller dealership, and he transitioned into a DLS employee when Bill and Glenda van Logtenstein purchased the company and started DLS. Steve has always worked in the installation and service aspects of the company.

Prior to being here, he worked in construction and gave factory work a try, but clearly, that was not his calling!

When he’s not at work, Steve enjoys camping, fishing and playing guitar.

Steve’s future plan is to continue doing what he’s doing and continue improving the DLS products.

He’s also looking forward to retirement someday! Home improvements are also something he continually finds himself doing. There are always challenges when you take on these projects, and he says he’s come across many! It seems he’s always working on improving something at home and at work!

Product of the Month

Since 2015, DLS has been fabricating complete parallel parlours in-house equipped with GEA milking equipment. The individual indexing model is the most popular. Individual indexing properly aligns cows in the parlour stall so that cows of varying sizes can stand next to each other while adequately positioned for cow comfort and easy udder access. These include stainless steel cabinets, galvanized parlour frames, and galvanized parlour stalls. A group indexing stall is also available and is beneficial in a retrofit scenario where there are height restrictions due to a lower ceiling.

As announced in our featured project story above, we are very excited to now be partnered with GEA to sell our parlours exclusively through GEA dealerships. For our local customers, we maintain the direct sale of our parlour stalls within our primary milking territories.

Key DLS features include:

- Individual indexing

- Individual release

- Vertical lift rapid exit,

- 68” clearance under lift rail

- Gravity-closed sequence gates

- Adjustable stall centers

- A proven low maintenance air system

- An installation-friendly modular system.

JOB PROGRESSION HIGHLIGHTS

Arthur, ON

Laros Farms

An upcoming D-10 parallel parlour and tunnel ventilated dairy barn!

Monkton, ON

Windulan Holsteins

The 50 stall GEA rotary started up on June 1!

Hague, SK

Foth Ventures

DLS automatic post dipper installed for this rotary!

DLS Parlour Fabrication Process

Check out our parlour stall fabrication process in our new dedicated DLS fabrication facility!