Featured Project

BRENT VINK

Brent Vink grew up with farming backgrounds on both sides of the family tree. His Dad, Lawrence, has worked on dairy farms throughout his life and expanded into custom harvesting and running a cash crop and finish pig operation. Brent developed a passion for agriculture as he grew up on the farm and began to work on a couple of dairies himself. These experiences led him to pursue his interest in agriculture through his post-secondary studies at the University of Guelph.

After his first year at the University of Guelph, Brent applied to both the New Producer Program and the New Entrant Program and reapplied the following two years for the New Entrant Program, but was unsuccessful all three times. Brent purchased 35 kilos of quota through the New Producer Program after being on the list for a little over 4 years. He found a barn to rent to milk the cows, and he has plans to purchase the farm in the future.

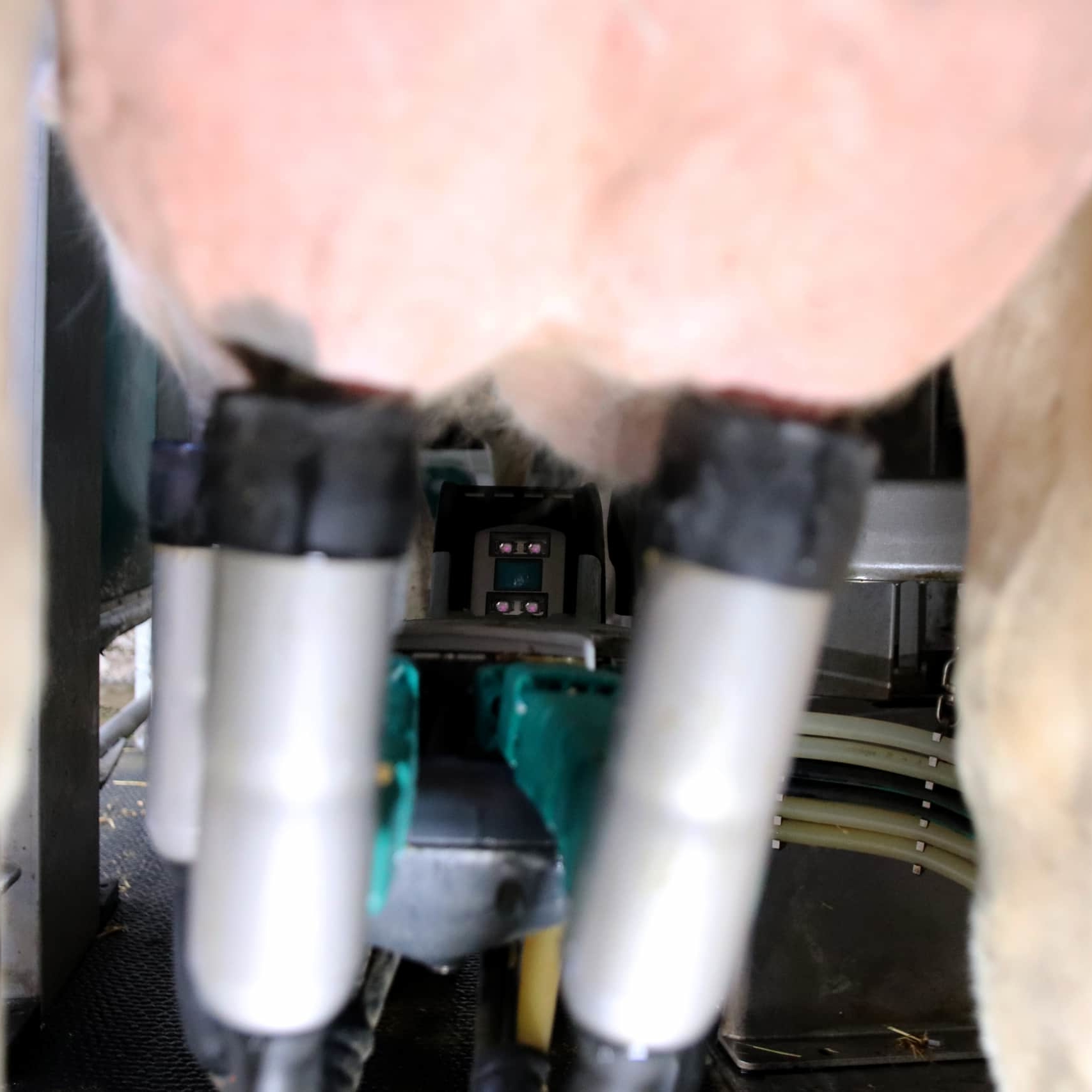

The dairy barn had 60 free stalls and was last operating as a dairy in 2001. With 20 years of no dairy, the barn required some work to prepare it for cows again! Going robot in the barn was a natural choice for Brent as this would allow him to continue his full-time job on a neighbouring dairy farm. Barn renovation decisions would be based on making the robot layout possible.

Barn renovations included placing the robot at the old parlour entrance and filling in the old parlour pit to create a special needs pen behind the robot. A maternity pen will be created as well later this year. The free stalls were modified with new mattresses and the Jourdain waved neck rail, and DLS tip troughs were installed for drinkers. One of the challenges heading into summer is ventilation in the old barn. DLS panel fans will soon be installed to help with this.

In choosing the GEA robot, Brent says that “The ability to measure and divert individual quarters

was my favorite feature. I also really liked the ability to manually attach with a pit behind the cow, and I liked not having the robot arm moving in the room. After starting up and operating for over 4 months, I have come to really enjoy the low noise level of the robot”.

Brent’s entire herd came from a single local dairy that was milking in a herringbone parlour with a newer free stall barn bedded with sand. The cows have transitioned to a milking robot in an older barn with a mattress bedding and a new feed ration. Of course, this was a lot for them to learn and adjust to, but they have done well! After 4 months their average butterfat is now steady at 4.0% with a daily average of 3.1 milkings per day. Brent says that “Not starting with a robot near full capacity gave the cows a better chance to go in on their own when learning the robot, which now means we rarely fetch any cows.”

Congratulations to Brent Vink on entering the dairy industry and on his retrofit GEA robot facility!

Employee Spotlight

Matt Davies

Warehouse/Yard Attendant

Joined DLS October 2020

Matt’s a relatively new employee who’s been working with DLS in the yard and warehouse for the past 5 months. He has had a diverse working background prior to working here, including working as a plumbing assistant and working for Pepsi doing full-service vending.

Matt comes from a family of 5 and is the youngest with 2 sisters and 2 brothers. He likes to partake in any and all watersports when he’s not working, from boating and tubing to fishing. Put him near water, and he’s a happy guy!!!

After having experience at DLS in the warehouse, Matt has ambitions to help build a barn from start to finish to round out his understanding of the business. He feels that would increase his knowledge in the warehouse to see the “big picture”! Seeing how things go together would help him better comprehend how the parts work and ensure parts are always picked and sent to the job site accurately. Matt also has an interest in welding.

In the future, Matt desires to go back to school and take business courses (sales) on a part-time basis.

Product of the Month

We’ve had a few warmer days and we all know the heat waves are just around the corner! It’s never too early to start thinking about how you plan to keep your cows cool and comfortable. Which will in turn keep your milk production up!

The DLS X-Brace panel fan is 54” with 5 blades. It is designed to work well in free stall areas and areas that need extra airflow. This fan features an energy-efficient enclosed motor and is super quiet! All the components are made in North America, and DLS offers a 5-year bearing and shaft warranty.

JOB PROGRESSION HIGHLIGHTS

Woodstock, ON

View Hill Holsteins

The barn addition at View Hill Holsteins is progressing well with the pack area all set up with cows and the rest of the barn stabling in progress. On the exterior, DLS curtains are installed.

Southwest Middlesex, ON

Macksvilla Farms

Congratulations to the Tower family at Macksvilla Farms on a successful startup on March 22. The cows transitioned from their rotary parlour to 3 GEA R9500 robots. The old rotary is getting pulled out to create calving pens.

Thedford, ON

Van Engelen Dairy

Congratulations to the Van Engelen family on moving into their new DLS Structure, complete with DLS curtains, DLS X-brace panel fans, Jourdain stabling and GEA manure equipment! They now have two DLS Structures side by side. The cows walk across the first DLS Structure to be milked in their existing parlour.

Easy Swing Brush = Comfortable Cows

Cows love the Easy Swing brush! From “The Head & Neck Scratch” to “The Bum Itch,” “The Full Swing,” and “The Comeback,” the Easy Swing brush is a simple, inexpensive solution to provide your cows with more comfort. We have sizes for heifers and calves too.